Kaolin

November 20, 2023

Calcium Carbonate

November 20, 2023

Micronized Mica Powder

Mica (Hydrated Potassium Aluminum Silicate)

Mica, known as muscovite glass, is the most common type of mica. Muscovite (hydrated potassium aluminum silicate) derives from the ideal structure of talc and pyrophyllite in environments that had been rich in aluminum, potassium, sodium, or calcium ions, in such a way that aluminum has replaced one-quarter of the tetrahedral silica, and potassium has been added between the layers to maintain electrical neutrality. The bond between the muscovite layers is weaker than its internal bonds, evident in its one-directional cleavage but stronger than that of pyrophyllite, making muscovite feel less greasy. Muscovite forms as a primary igneous mineral in granites and silica-rich rocks and is a major component of many metamorphic rocks and sedimentary schists.

Structure:

It crystallizes in the monoclinic system, often as flat, pseudo-hexagonal crystals. It is scattered as thick sheets in igneous rocks, as streaks in schist and gneiss, and also as clay in sedimentary rocks. It has perfect one-directional cleavage and separates into sheets with rough edges but is elastic and robust. It is colorless, gray, light green, brown, yellow, rose, or purple. Its streak is white. It has a glassy or pearly luster. It varies from opaque to translucent and is transparent when in thin sheets. It has a Mohs hardness of 2 to 3 and a specific gravity of 2.7 to 3.1.

Properties:

Mica sheet with ceramic glue is known as a ceramoplastic insulator. A type is produced with artificial mica flake and glass glue. Heavier sheets with glass glue are also produced for frames and parts of electronic devices. Mica paper and mica mesh, typically produced with an organic adhesive to create flexibility, include one of the oldest mica papers, named Watsonite, which is made of natural mica flake that has been dehydrated by heat and sheeted with resin glue. Many mica papers have excellent insulation resistance, but their thermal resistance is limited by their glue.

Transformer grade mica, used for Class H insulation, may be made with silicone glue. Sheets 0.05 millimeters thick have an insulating resistance of 32 volts per micron and a tensile strength of 7 kilograms per square millimeter. The first artificial mica was made by melting a mixture of 11.6% alumina, 32.6% magnesium oxide, 30.7% cryolite, and 25.1% K2SiF6.

Applications:

Plastics are often filled with mica powder and traded as sheets, pipes, and molded parts, but are distinct from mica ceramics, which are molded with organic glue and usually have superior physical properties.

A mixture of mica with lead borate forms lead borosilicate, which upon casting has good strength and resistance to water and bending, and a low coefficient of expansion. Molded parts have a specific gravity of 3.8, a bending strength of 4.8 kilograms per square millimeter, a Rockwell hardness of 110 M, and a working temperature of 650°C.

The first mica substitute during the war, known as "Glashart Gobain," was made by saturating very fine glass fiber cloth with high alkali with a kaolin osmosis solution in alcohol and a synthetic resin and then compacting it at high heat. It has also been made with bentonite and asbestos fiber wetted with ethyl silicate.

Ultra-fine glass fibers are produced in papermaking machines as sheets 0.15 to 0.3 millimeters thick in continuous coils 96 centimeters wide. They withstand temperatures up to 650°C, with insulation resistance greater than natural mica.

For capacitors and transformers, sheets 0.02 to 0.0425 millimeters thick are made with thin glass fiber and a tetrafluoroethylene resin glue, which is stiffer and stronger than ordinary thin plastic layers, with an insulation resistance of 160 volts per micron and a working temperature of 250°C.

Glass paper is made from borosilicate glass flake and an alkyd, phenolic, or silicone resin glue. Where there is no excessive heat, various thin plastic layers are used for insulating grooves.

The use of mica powder in the production of cosmetics

Application of mica powder in rubber making

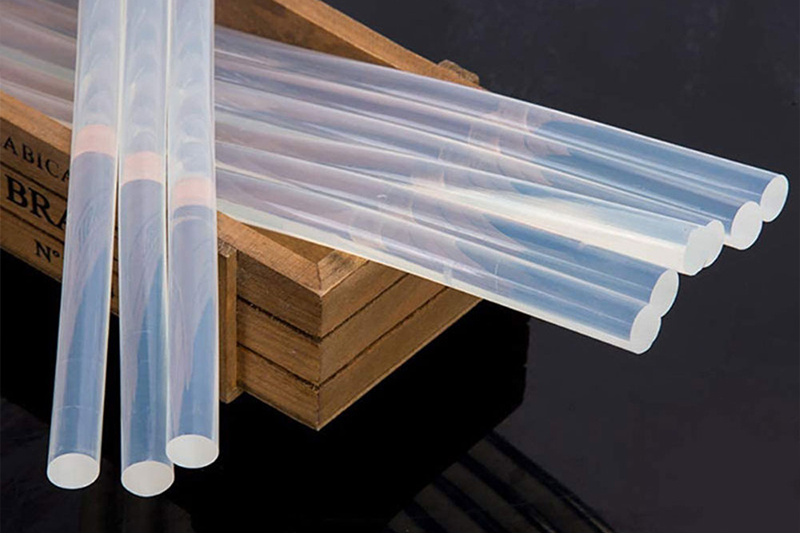

The use of mica powder in the production of glue

Application of mica powder in coloring